Hands down, the best sliders on the market

A bulletproof product

"The team did a great job of engineering a bulletproof product with easy to follow instructions." - J. McGovern, Rivian Stories Co-Founder

Installed Electruck4x4 Megawatt R1T Rock Sliders. TLDR: They Rock!

A large step above the competition

"I have been in the fabrication business for over 38 years. From the design, to the welds, the Megawatt Sliders are a large step above the competition." - Terry K.

I have the Megawatts and they have been perfect.

Real pleased with the quality of the Megawatt sliders and ease of install.

"Awesome product"

"They look amazing!!!! Thank you Electruck4x4 for making such an awesome product!!"

Current estimated lead-time: approximately 1 weeks from order placed date.

The Rivian R1T is the perfect vehicle to tackle the outdoors. Its high ground clearance and individual wheel control enable it to navigate rocky terrain with ease. Even the most capable vehicles and drivers, however, can get hung-up on rocks and logs, which can result serious rocker panel damage or worse. Rock sliders help guard against this off-road hazard to keep your truck protected.

Unsatisfied with current Rivian offerings, a team of early owners and longtime off-roaders assembled to engineer the strongest rock slider on the market that can serve as an R1T running board, yet stand up to even the most punishing abuse. What they arrived at is the latest product from Megawatt™ performance products.

Make no mistake, this product is a rock slider first with the added benefit of serving as a convenient Rivian step. Conflating these two types of accessories can put you and your truck as risk. Given the weight of the Rivian R1T, and the potential for extreme forces while off-roading, we felt a purpose-built protection solution be crafted first. Only then could added features like a running board step be added.

The Rivian R1T has a curb weight of over 7,100 lbs. That is close the weight of a Dodge RAM 3500 MegaCab. As such, we used proven slider methods for vehicles like these to benchmark the Megawatt™ Rivian R1T rock slider. We then adapted this formula to fit the lines and unique architecture of the Rivian. The result is not only a rock solid, highly functional slider, but a side-step that looks great.

This product fits 2024 and older R1T vehicles only

Installation instructions can be found here.

MEGAWATT™ ROCK SLIDERS

| Feature | MEGAWATT™ | COMPETITOR 1 | COMPETITOR 2 | COMPETITOR 3 |

|---|---|---|---|---|

| 🔨 Construction | ✅ Fully enclosed tubing | ✅ Fully enclosed tubing | ❌ Press broken sheet metal | ❌ Press broken sheet metal |

| Why It Matters: Sheet metal is often used because it costs less than enclosed tubing. Unfortunately, this folded structure relies on just a few corner welds that can split apart on impact. | ||||

| 🔩 Mounting Points | ✅ Two rows of bolts | ❌ One row offset | ✅ Two rows of bolts | ✅ Two rows of bolts |

| Why It Matters: Single row mounting allows the slider to flex when pushed upward, leading to body damage. | ||||

| ⚙️ Rail Mounting | ✅ Inline with frame | ❌ Cantilevered outside | ✅ Inline with frame | ✅ Inline with frame |

| Why It Matters: Offsetting mounts creates additional outside leverage when the rail is pushed up, which can cause flex and frame damage. | ||||

| 📏 Rail Thickness | ✅ .188" | ❌ .134" | 🤷♂️ Undisclosed | 🤷♂️ Undisclosed |

| Why It Matters: Thicker rails withstand more force without crushing or bending. | ||||

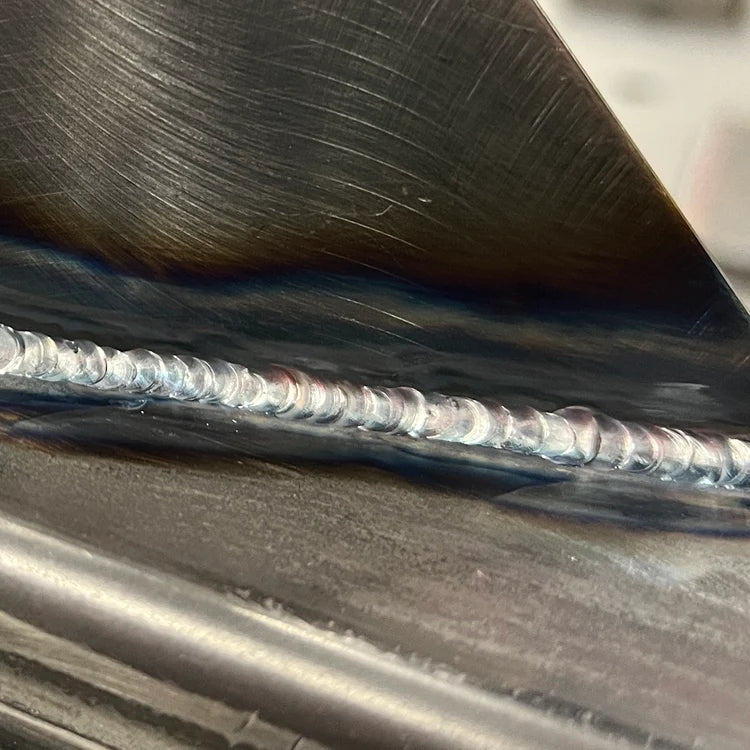

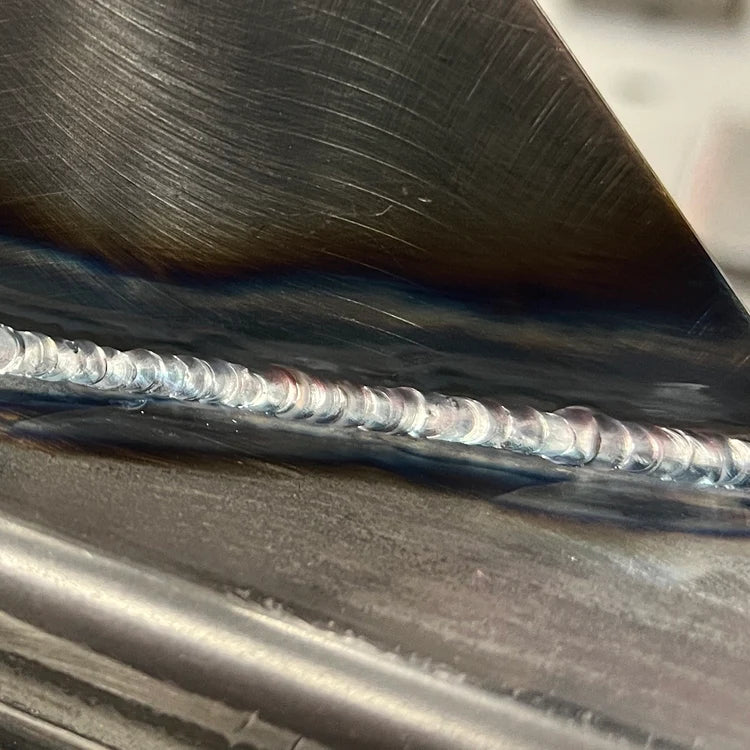

| ⚡ Weld Type | ✅ TIG | ❌ MIG | ❌ MIG | ❌ MIG |

| Why It Matters: TIG welding results in cleaner, stronger welds than MIG. | ||||

| 🛡️ Coverage | ✅ Full wheel-to-wheel | ❌ Mostly wheel-to-wheel | ❌ Mostly wheel-to-wheel | ❌ Mostly wheel-to-wheel |

| Why It Matters: Partial coverage leaves vulnerable areas open to rock damage. | ||||

| 👢 Kick-out | ✅ Yes | ❌ No | ❌ No | ❌ No |

| Why It Matters: Provides stepping platform, additional protection, and obstacle pivot point. | ||||

| 🔧 Underside Cover | No | No | Yes | No |

| Why It Matters: Underside plating traps debris while providing only marginal protection. | ||||

| 💰 Price Point | $$$ | $ | $$ | $$ |

| Why It Matters: Premium price reflects premium materials and construction. | ||||

- Falls Short: Single row mounting, cantilevered design

- Falls Short: Thinner material (.134" vs .188")

- Falls Short: MIG welds, partial coverage

- Falls Short: No kick-out design

- Falls Short: Sheet metal construction

- Falls Short: Undisclosed rail thickness

- Falls Short: MIG welds, partial coverage

- Falls Short: No kick-out design

- Falls Short: Sheet metal construction

- Falls Short: Undisclosed rail thickness

- Falls Short: MIG welds, partial coverage

- Falls Short: No kick-out design

ENGINEERED FOR SUPERIOR STRENGTH

Premium materials. Premium construction. Premium performance.

What the Pro's Are Saying:

We are very happy with the Megawatt™ sliders. They have saved our R1S from damage countless times. While we do keep an eye on students, they aren't always gentle on our Rivians. Our trucks see weekly use in technical terrain and having quality protection helps keep damage to a minimum. We have had to use the Hi-Lift jack several times to lift the S off rocks and the Megawatt™ sliders have held up to that lifting force. Truly a solid addition to protect the door sill and under body bits!!! Thanks for making a durable and reliable slider for my R1S.

- Bill Burke, Professional Off-Road Racer, Rivian Off-Road Instructor, and Owner of 4-Wheeling America

CONSTRUCTION

100% DOM (drawn over mandrel) USA steel

Main slider:

- 2" diameter box steel

- .188" thickness

Rub rail:

- 1.75" diamter tube steel

- .120" thickness

Mounting brackets:

- .125" plate

Weight:

- Approximately 65 pounds per side

FINISH

Each slider is enveloped in flat black via a unique four-stage process.

- Each slider and its top plate is coated in primer.

- Top plates are welded to the slider

- Assembled sliders are powder coated in a high-heat oven

- A probe is inserted and run the length of the tube to coat the inside with paint

We realize this might sound like a lot of work to coat a piece of metal. (It is)! However, this process ensures maximum coverage, which in-turn improves corrosion resistance and longevity.